Waste Management System

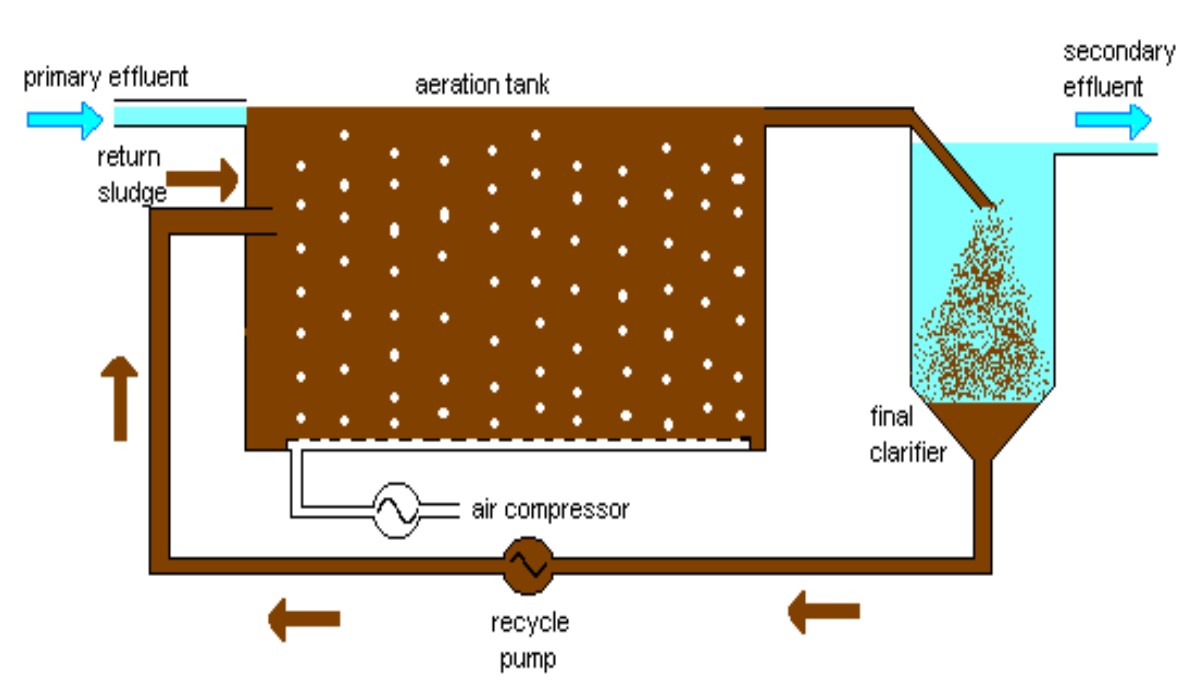

ACTIVATED SLUDGE PROCESS

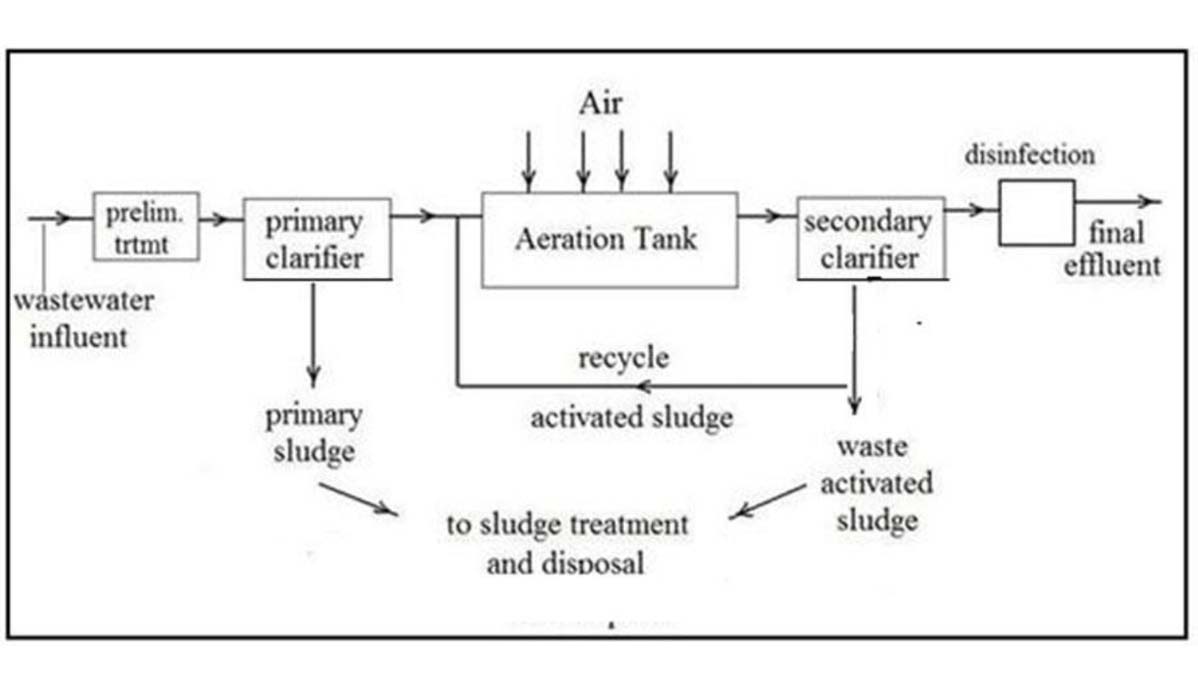

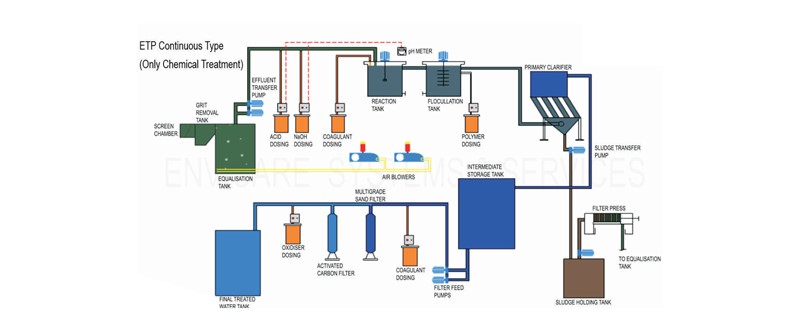

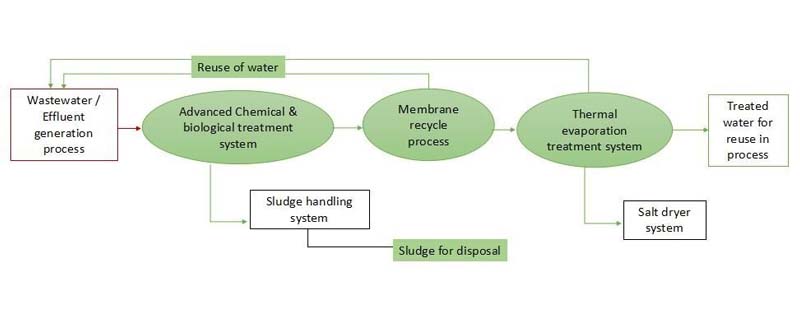

FLOW CHART FOR ETP

Water scarcity and contaminated drinking water is a great challenge in the 21st century. Industrial wastewater of various industries undergoes series of treatment processes before being discharged to the environment. Such Effluent Treatment Plant (ETP) normally employs primary and secondary treatment methods mainly to reduce the contaminant levels in wastewater. However due to increased burden on natural water resources it is now necessary to recycle and reuse wastewater to improve water utilization efficiency.

We offer wide variety of innovative and integrated solutions to treat highly complex wastewater containing high amount of COD, BOD, inorganics, TDS and other contaminants.

There are several approaches to treat and recycle wastewater depending on feed water quality and end use. Mostly, these approaches consist multiple steps and stages involving many individual unit operations. This may include biological treatment, multimedia filtration, activated carbon treatment, chemical softening, ion exchange units, cartridge filtration, ultrafiltration and reverse osmosis.

Our modular and containerized effluent treatment plants (ETP) are highly efficient, compact and robust that allow clients to maximize their resources in a most optimized way.

Application

- Common Effluent Treatment Plant (CETP) wastewater

- Contaminant water from dyes plant

- Wastewater from tannery industries,

- Waste water from food industries reuse thereafter

- pharma industries effluents for treatment and recycle

Technologies

- Membrane Bioreactor (MBR)

- Ultrafiltration (UF)

- Reverse Osmosis (RO)

- Forward Osmosis (FO)

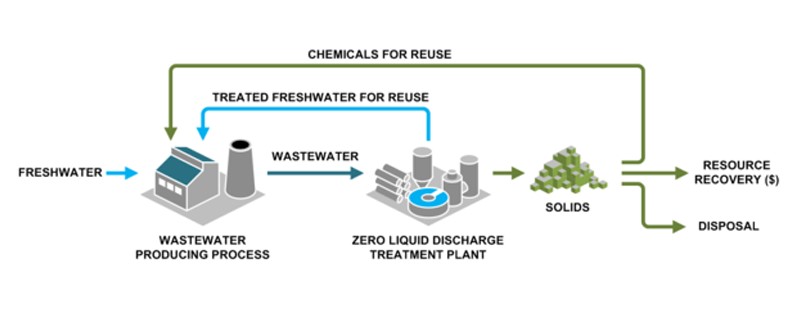

ZERO DISCHARGE LIQUID

ETP using MBR

Benefits

- Clean reusable water

- Saves you money —Ensures complying with industry standards and regulations.

- Saves our Mother Earth

- A way to minimise waste steps toward Clean Environment